vickers hardness test procedure pdf|rockwell hardness test procedure pdf : Brand Our advanced Macro Vickers hardness tester 3842 is a state-of-the-art, precise testing system suitable for hardness analysis of metallic specimens in metallography laboratories or . 11/10/2022 04h00. O radialista e evangelizador Fabio Teruel (MDB) foi eleito deputado federal por São Paulo. O candidato foi o 14.º mais votado, com 235.165 votos. O número .

{plog:ftitle_list}

webThayse Klöppel (@thaysekloppel) • Instagram photos and videos. 357K Followers, 1,003 Following, 440 Posts - See Instagram photos and videos from Thayse Klöppel (@thaysekloppel)

1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness .

This part of ISO 6507 specifies the Vickers hardness test method, for the three .

This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force

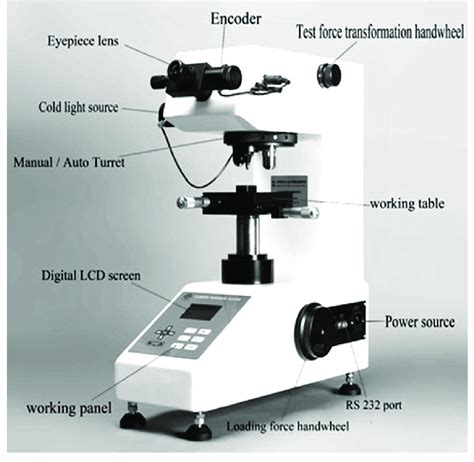

Our advanced Macro Vickers hardness tester 3842 is a state-of-the-art, precise testing system suitable for hardness analysis of metallic specimens in metallography laboratories or .

METHOD FOR VICKERS HARDNESS TEST FOR METALLIC MATERIALS ( Third Revision) 1 Scope This part of ISO 6507 specifies the method of Vickers hardness test for the three .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Vickers and Knoop hardness test principle: An indentation hardness test using a verified machine to force an indenter, under specified conditions, into the surface of the material under .This document specifies a method of verification and calibration of testing machines and diagonal measuring system for determining Vickers hardness in accordance with ISO 6507-1. A direct .E691 Practice for Conducting an Interlaboratory Study to 3.2.2 microindentation hardness test, n—a hardness test, Determine the Precision of a Test Method 3 normally in the Vickers or Knoop scales, using test forces in 2.2 ISO .

The Vickers test is the standard method for measuring the hardness of metals, particularly those with extremely hard surfaces: the surface is subjected to a standard pressure for a standard length of time by means of a pyramid .This document specifies the Vickers hardness test method for the three different ranges of test force for metallic materials, including hard metals and other cemented carbides (see Table 1), .F ≥ 49,03 ≥HV 5 Vickers hardness test 1,961 ≤ F < 49,03 HV 0,2 to

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . 5.3 Because microindentation hardness tests will reveal hardness variations that commonly exist within most materials, a single test value may not be representative of the bulk hardness. Vickers tests at 1000 gf can be utilized for determination of the bulk hardness, but, as for any hardness test, it is recommended that a number of indents are made and the average .The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. . Test) is a standardized test procedure used to determine the hardenability of steel, and it can be performed using any Vickers micro hardness tester. The procedure is described in the following standards: ASTM A255 / ISO 642 / DIN .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

Download Free PDF. Download Free PDF. Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials 1. . Appendix X1 1.4 This test method covers Vickers hardness tests made utilizing test forces ranging from 9.807 × 10-3 N to 1176.80 N (1 gf to 120 kgf), and Knoop hardness tests made utilizing test forces from 9.807 × .

is the 2ns powerprep test harder than the actual gre

The best hardness test method and corresponding load depend on the material to be tested, the component shape, applica-tion, and the customer requirements. After process of elimination, there are often only a few options left. . The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements,

1. rockwell hardness test 10 2. vickers hardness test 13 3. impact test 16 4. tensile test 21 5. compression test 26 6. shear strength test 29 7. heat treatment 32 8. wear test 35 9. microstructure 39 10. brinell hardness test 43 11. torsion test 46 12. fatigue test 49 13. bending test 53 14. ultrasonic test 56 15. magnetic particle test 58higher. At lower test loads the Vickers hardness may be load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). N. ote

vickers hardness testing machine diagram

An original image of a Brinell hardness indentation a) and its histogram b). Figure 5: Processing of a Vickers hardness indentation image: a) original image, b) binarized resultant image and c .The Vickers hardness test is specified in this document for lengths of indentation diagonals between 0,020 mm and 1,400 mm. Using this method to determine Vickers hardness from smaller indentations is outside the scope of this document as results would suffer from large uncertainties due to the limitations of optical measurement and . Note 1: The Vickers and Knoop hardness numbers were originally defined in terms of the test force in kilogram-force (kgf) and the surface area or projected area in millimetres squared (mm 2).Today, the hardness numbers are internationally defined in terms of SI units, that is, the test force in Newtons (N). However, in practice, the most commonly used force .

The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384). 5.1 For advanced ceramics, Vickers indenters are used to create indentations whose surface-projected diagonals are measured with optical microscopes. The Vickers indenter creates a square impression from which two surface-projected diagonal lengths are measured. Vickers hardness is calculated from the ratio of the applied force to the area of contact of the .3.1.3 Vickers Hardness Test The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Further information regarding existing standards and procedures can be .

3.1.1 Vickers hardness number (HV), n—an expression of hardness obtained by dividing the force applied to a Vickers indenter by the surface area of the permanent impression made by the indenter. 3.1.2 Vickers indenter, n—a square-based pyramidal-shaped diamond indenter with face angles of 136° 008. 4. Summary of Test Method 4.1 This test .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .low-force hardness test Vickers hardness test using an applied force greater than or equal to 1,961 N, but less than or equal to 9,807 N 3.2 microhardness test Vickers hardness test using an applied force less than 1,961 N Note 1 to entry: Vickers hardness tests in the low-force range and Vickers microhardness tests give different

[1] ISO 6507-4, Metallic materials — Vickers hardness test — Part 4: Tables of hardness values [2] ISO 18265, Metallic materials — Conversion of hardness values [3] ISO 23718, Metallic materials — Mechanical testing — Vocabulary [4] JCGM 100:2008 (GUM 1995 with minor corrections), Evaluation of measurement data - Guide to the expression of uncertainty in .Metallic materials -Vickers hardness test -Part 1: Test method (IDT). Goncharova I.V. Harakteristika plastichnosti, opredelyaemaya metodom indentirovaniya. Voprosy atomnoj nauki i Devices and .2. Slow. Testing can take 30 seconds not counting the sample preparation time. 3.2 Vickers Test The Vickers (HV) test was developed in England is 1925 and was formally known as the Diamond Pyramid Hardness (DPH) test. The Vickers test has two distinct force ranges, micro (10g to 1000g) and macro (1kg to 100kg), to cover all testing requirements.

Hardness Test 2/5 the microscope is in millimeters. The larger diameter indentation corresponds to a softer material and lower Brinell number. VICKERS HARDNESS TEST The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degreesSC 3, Hardness testing. This first edition cancels and replaces Annexes B, C and D of ISO 6507-1:1997. ISO 6507 consists of the following parts, under the general title Metallic materials — Vickers hardness test: ⎯ Part 1: Test method ⎯ Part 2: Verification and calibration of testing machines ⎯ Part 3: Calibration of reference blocksMetallic materials — Vickers hardness test — Part 4: Tables of hardness values 1 Scope This document gives tables of Vickers hardness for use in tests carried out in accordance with ISO 6507-1. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content

%PDF-1.4 %ÓôÌá 1 0 obj /Type/Catalog /Pages 2 0 R /Metadata 136 0 R /Outlines 331 0 R /PageMode/mlfjlu >> endobj 2 0 obj /Type/Pages /Count 12 /Kids[20 0 R 31 0 R 41 0 R 43 0 R 45 0 R 47 0 R 66 0 R 73 0 R 114 0 R 116 0 R 118 0 R 135 0 R] .

among Brinell hardness, Vickers hardness, Rockwell hardness, Rockwell superficial hardness, and Knoop hardness of copper. 1.8 Conversion Table 8 presents data on the relationship

vickers hardness test manual

rockwell hardness test procedure pdf

webAssistir Private Property filme? Descubra onde assistir online entre 15 serviços de streaming, como Netflix, MEO, FoxPlay etc.

vickers hardness test procedure pdf|rockwell hardness test procedure pdf